ARCHITECTURE

CRANE WASP

Crane WASP

The Infinite 3d printer

Crane WASP, a collaborative 3D printing system capable of printing houses, contained in the Maker Economy Starter Kit, print material found at Km 0 as our guide symbol: the vasaia wasp.

TECHNICAL DETAILS

3D PRINTING INFORMATION

Printing volume: Ø6300mm x h3000 mm

Minimum layer height: 9 mm

Maximum printing speed:300 mm/s

Maximum travel speed: 500 mm/s

Acceleration:20 mm/s2

Nozzle diameter:from 18 to 30 mm

MATERIALS

Earth based materials

Concrete mortar

Geopolymers

CONFIGURABLE TOOLS

LDM WASP XL EXTRUDER:nozzle diameter from 18 to 30 mm

SOFTWARE

Operative systems: Windows

Slicing software: Grasshopper

File type: .gcode

INTERFACE

WiFi remote control

PHYSICAL DIMENSIONS

Dimensions:column height 4050 cm, arm length 3300 cm

Machine weight: 150 kg

SUPPLY

Input 220/240 V 50/60 Hz

Absorbed power:1500 W

TEMPERATURE

Use 10-40 C°

Warehouse0-30 C°

MECHANICS

Frame: Steel, aluminium

Crane WASP

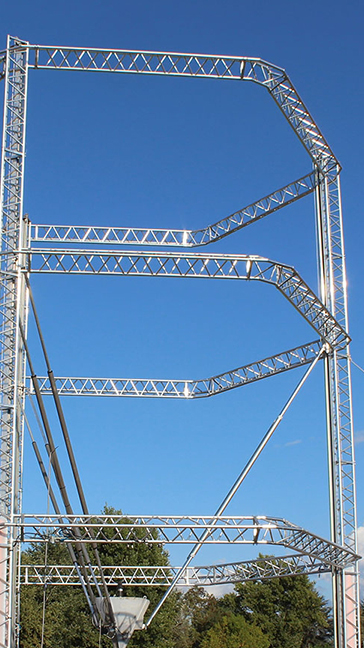

Crane WASP The Infinity 3d printer is a modular collaborative 3D printing system. It reinterprets the classic building cranes from a digital manufacturing point of view. It is composed of a main printer unit that can be assembled in different configurations depending on the printing area and therefore on the dimensions of the architectural structure to be calculated in 3d. The print area of the single module is 6.60 meters in diameter for a height of 3 meters.

The single module can work self-sufficiently by printing fluids of different kinds: cement, bio cement, natural dough. Once you have a single module, you can expand it by adding traverses and printer arms, thus generating an infinite digital manufacturing system.

It is not necessary to “cover” the entire area involved in the construction with the printing area of the WASP Cranes because they can be reconfigured and can advance with generative attitude depending on the growth and shape of the building. More WASP Cranes, when working together, have a potentially infinite printing area and can be set by the on-site operators following the evolution of the architectural project.

3d Printer House

The evolution of the Big Delta 12MT allows us to reduce the mechanical dimensions of the printer while maintaining a large print area. Created with the same modular mechanical components used to make up the Big Delta 12M aluminum structure , it is a fast and efficient tool to be dismantled and reassembled for an easy transport.

Contained in the Maker Economy Starter Kit, it too is designed to be able to print on-site natural mixes at 0km, with the addition of natural fibers for architectural-scale construction. The container, transported on site, offers all the necessary tools to build a self-sufficient village through the most advanced additive technologies. Depending on the territory and the project, one can choose the optimal printing configurations, by assembling each single module in different ways. All components are transported disassembled. The basic tools included in the kit together with the printer, are those dedicated to the mixture: muller and tumbler

ARCHITECTURE

BIG DELTA

BIG DELTA WASP 12m

A Giant 3D printer resulted from a research project in the field of sustainable housing construction with locally available materials and low costs. This has been WASP’s primary objective since the very start.

TECHNICAL DETAILS

PHYSICAL DIMENSIONS

The 3D world-highest printer – 12 m. high – projected to build houses, now has become a realty and an Italian reality from WASP. The BigDelta configuration is in fact 12 m. high and 7 m. wide , assembled with 6 m. modular arms. All the machine-components have a maximum length of 3 m. so that they can be easily loaded on a trailer and transported.

3D PRINTING INFORMATION

The BigDeltaWASP 12m works with 220 volts but it can work with 60 volts too, because the engines and the electronic parts have been realized to be powered by solar panels. Three countermeasures reset weights involved, in this way the machine becomes a balanced system. This allows to reduce a lot the consumption, keeping them round 1 kilowatt. Although each engine, the extruder-one inclusive, are 400-watt engines, they never work using te same power.

The BigDeltaWASP 12m can move the extruder with a cargo from 0 to 200kg therefore moving big quantities of material. The only reason why we suggest to reduce the weight round 40-50 kg is to reduce vibrations.

MATERIALS

Even though the materials that can be extruded are several, the extruder has been studied to work with blends containing long fiber-materials. The reason of this choise is our project-heart: since the beginning we have been longing to extrude terrain and straw. So, it is not necessary to mince in smaller pieces the fiber, on the contrary it woks better when long.

We have experienced the usage with other inert materials too.

There are two possibilities: we can use raw materials of natural origin or specific techincal materials. For what concerns, raw terrain, it can be lightened with vermiculite or other natural light materials.

The sintetical or technical mixtures can be composed by cement materials based on lime together with or blown-glass either expanded clay. Very good result has been obtained adding polystyrene to the cement. This solution makes the mixture very light and reduces the costs, what we have not examined yet, is the impact that this solution may have on the environment.

It’s much easier to use synthesis-materials or technical materials than natural mixtures because they are still to be fully discovered. Even though our application field is adressed to the second ones: we are testing clay or straw blends with the addition of hemp or hemp derivates; or with the addition of blown materials (really odd is the application in which we add pop-corn inside the mixture to create air bubbles).

PRINTING SPEED

Fino ad ora abbiamo lavorato con una velocità massima di 400 mm/s. La rapidità di stampa dipende anche dalla quantità di materiale presente dentro l’estrusore. Il tema cruciale per quanto riguarda questa macchina non è la velocità ma l’accelerazione, anch’essa inversamente proporzionale al peso dell’estrusore. La possibilità di aumentare l’accelerazione richiede l’utilizzo di pompe esterne che azzerano il carico della macchina, rifornendo continuativamente l’estrusore di materiale.

APPLICATION FIELDS

The BigDeltaWASP 12m is suitable to print materials taken from the origin place and this opens the way to a series of innovative applications , considering both the house-building and the recovery of archeological rests or ruins.

SOME NUMBERS

270 centimetres of straw+clay wall have been printed; its diameter is 5 m. and 40 tons of mixture have been used. The total layers are 135, with an average weight of 300 kg each, average time to build a layer: 20 minutes. For what concerns the consumption: 2 cubic metres of water and 200 Kwh . Let’s talk about costs: 32 € for the energy employed, 3 € for the water, 10 € for the straw, 3 € for the petrol of the motor-hoe; in total 48 €. Do you want to spare more? If you use your feet to mix, you can reduce the costs of 90%.

Giant 3D Printer

A 3D printer resulted from a research project in the field of sustainable housing construction with locally available materials and low costs. This has been WASP’s primary objective since the very start.