Everything you need to go from design to fully functional metal parts — the Metal X is the best-in-class additive manufacturing solution.

Why Use a Metal 3D Printer?

Business Benefits

Get products to market faster

Reduce manufacturing costs

Improve supply chain efficiency

Technical Advantages

Easily 3D print complex geometries

Eliminate tooling spend

Safe, automated processes

Metal 3D Printing Materials

17-4 PH Stainless Steel

Combines high strength, corrosion resistance, and hardness. Used in a wide variety of manufacturing applications.

H13 Tool Steel

A hot-work tool steel with excellent toughness, wear resistance, and heat resistance. Excels in high temperatures.

A2 Tool Steel

Can be air-hardened up to 58 HRC; excellent impact resistance. Used for forming tooling, punches, and dies.

D2 Tool Steel

Can be air-hardened to 60 HRC; trades toughness for hardness and abrasion resistance. Great for cutting tools and dies.

Inconel 625

A proprietary nickel alloy that excels in high temperatures and corrosive environments. Used in automotive and aerospace.

Copper

Thermal and electrical conductivity. Print heat sinks, custom conductive elements, and other geometrically complex parts.

316L Stainless Steel

Exhibits excellent corrosion resistance. Used in marine applications.

Titanium Ti6Al4V

Superior strength-to-weight ratio. Used in aerospace, medical, and other high-performance fields.

Metal X System Overview

Markforged Metal 3D Printing Process

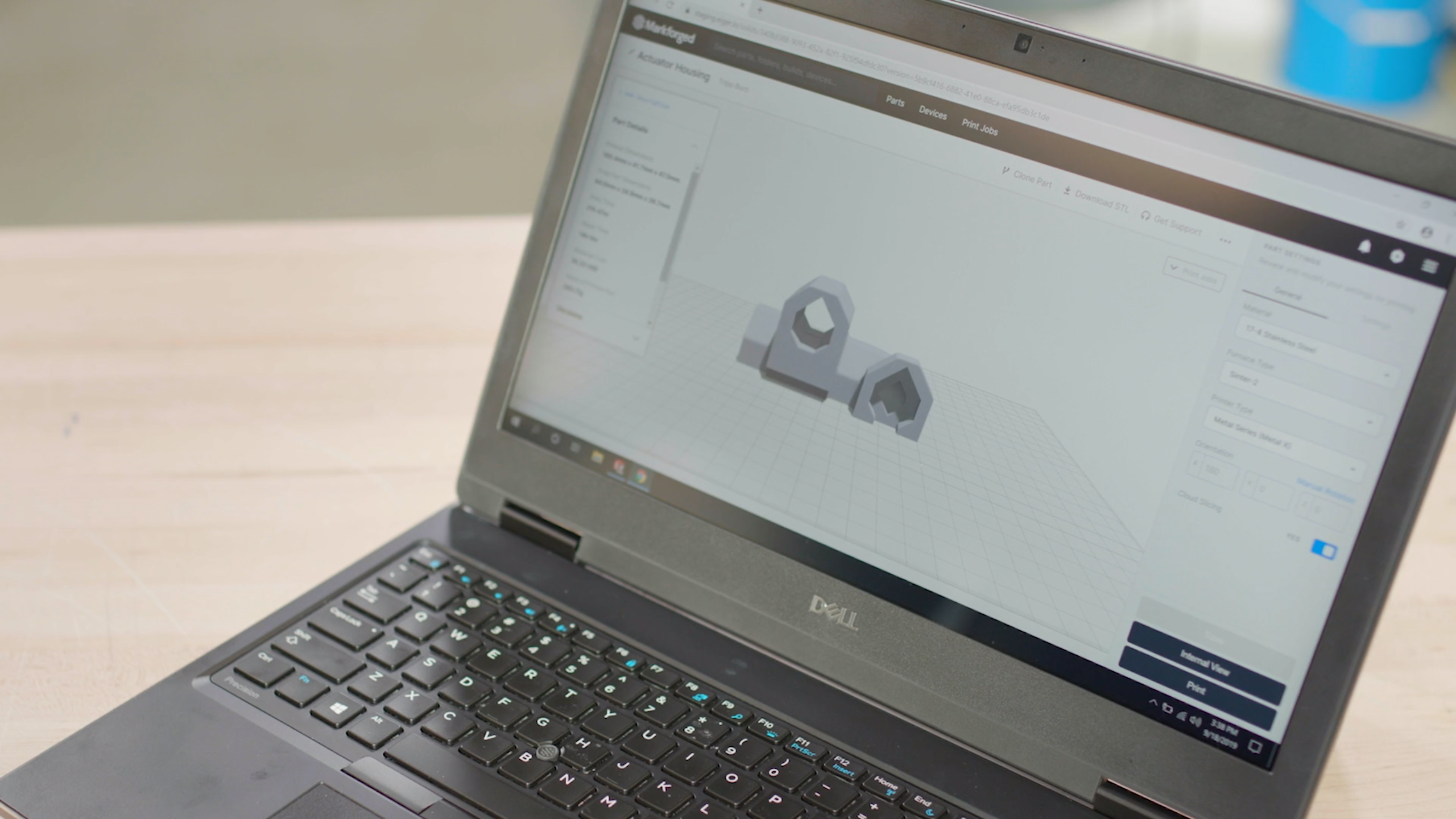

DESIGN & SLICE

CAD your part, upload the STL to Eiger, and select your material. The software slices your part, automatically generating supports where necessary.

Metal powder bound in plastic is printed a layer at a time into the shape of your part. Parts are scaled up to compensate for shrinkage during the sintering process.

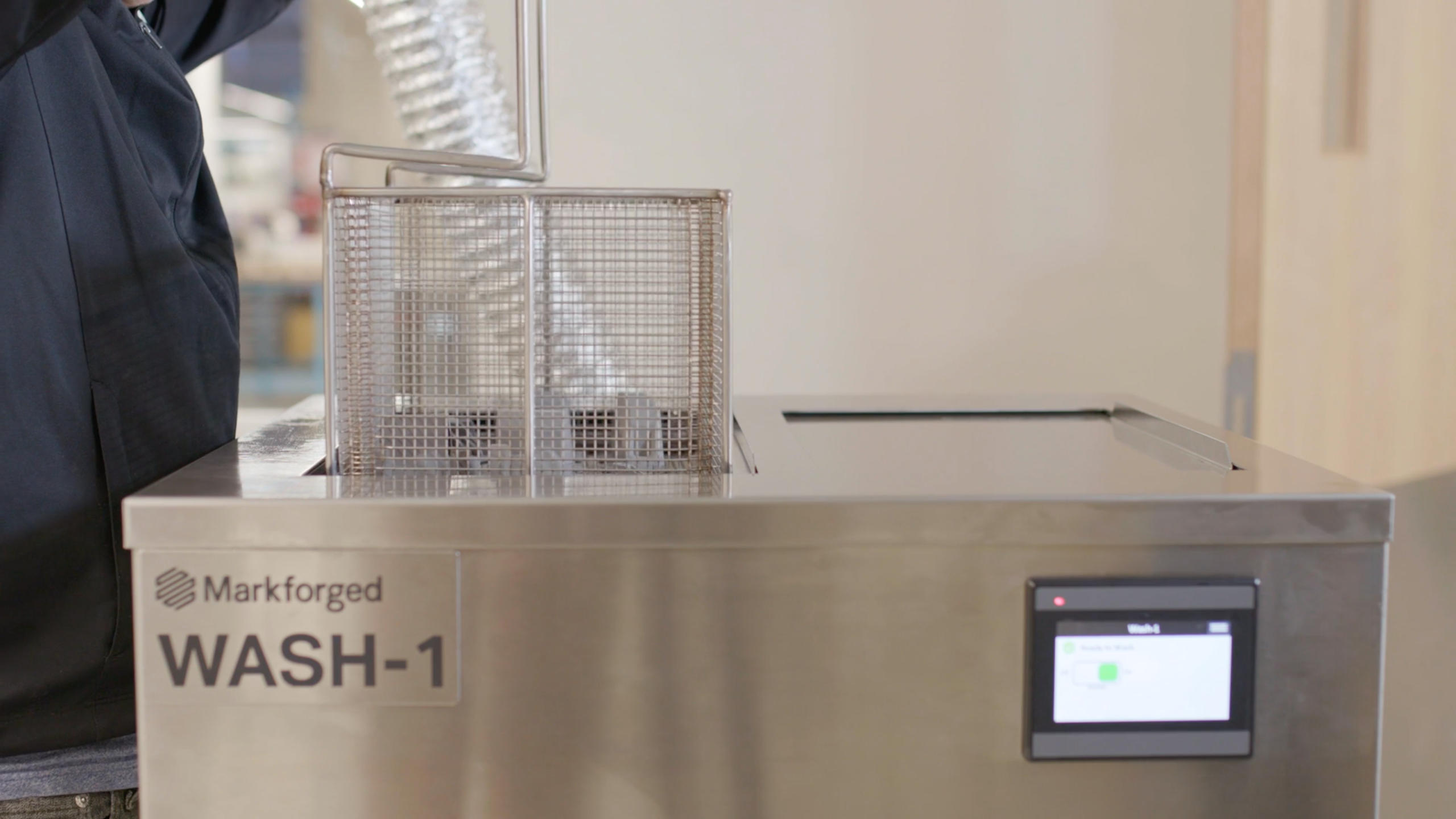

WASH

After printing, “green” parts are placed into the Wash-1, which uses a debinding fluid to dissolve most of the plastic binding material.

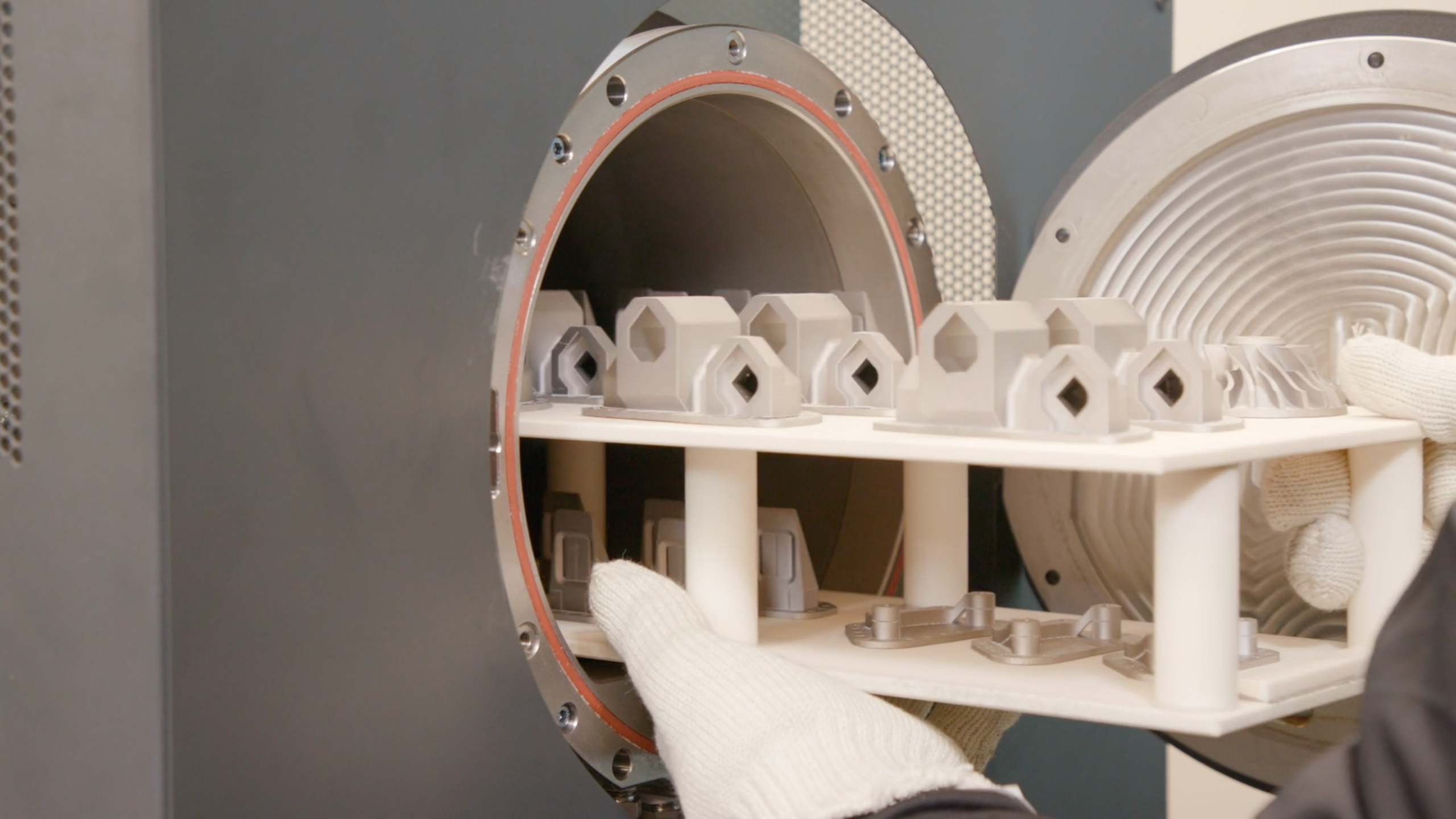

SINTER

Washed “brown” parts are placed in a Markforged furnace, where they are heated with a material-specific profile to burn away remaining binder and solidify metal powder.

Technical Specifications

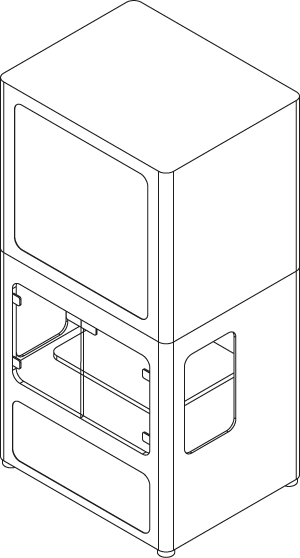

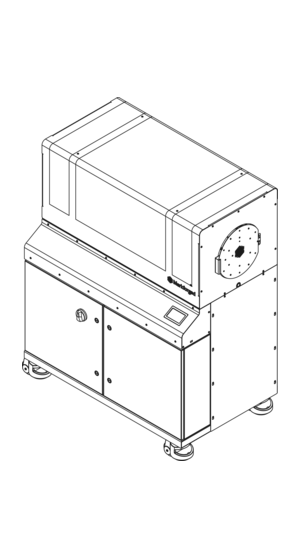

METAL X

Build Volume: 300 mm x 220 mm x 180 mm

Z-Resolution: 50 um - 125 um

Media: Filament fed, bound powder

Ext. Footprint: 575 mm x 467 mm x 1120 mm

Weight: 75 kg

Power Req.: 100-240 VAC, 2400 W

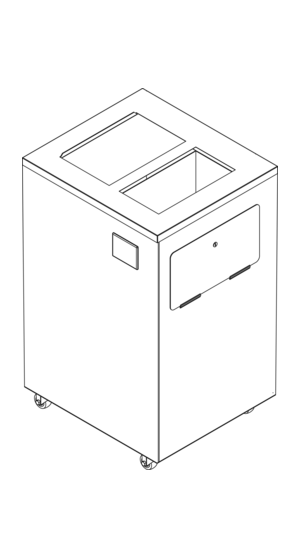

WASH-1

Solvent: Opteon SF79

Wash Times: 12 hours - 1 week

Ext. Footprint: 575 mm x 467 mm x 1120 mm

Weight: 136 kg

Power Req.: 100-240 VAC, 2400 W

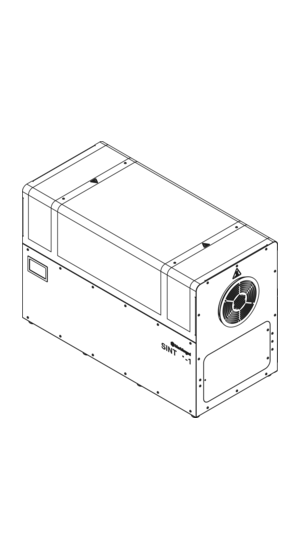

SINTER-2

Run Time: 30 hours

Gas Types: Argon, Argon/Hydrogen mix

Retort: High purity, Carbon free

Ext. Footprint: 575 mm x 467 mm x 1120 mm

Weight: 350 kg

Power Req.: 200-240 V, 3 phase, 30A OR 346-416 V, 3 phase, 30A

SINTER-1

Run Time: 26 hours

Gas Types: Argon, Argon/Hydrogen mix

Retort: High purity, Carbon free

Ext. Footprint: 575 mm x 467 mm x 1120 mm

Weight: 136 kg

Power Req.: 200-240 V, single phase, 36 A